83C Mittal Court, Nariman Point, Mumbai 400021, INDIA

Phone: +91 22 4002 0045/46 | Email: info@bmgindia.com

Global Consulting Company, Top Management Consulting Firm

© 2024 BMGI India

India Design & Engineering Services Centre of $ 8 BN diversified global manufacturer that delivers innovative equipment and components, consumable supplies, aftermarket parts, software and digital solutions and support services. The India Centre is responsible for providing design & engineering solutions.

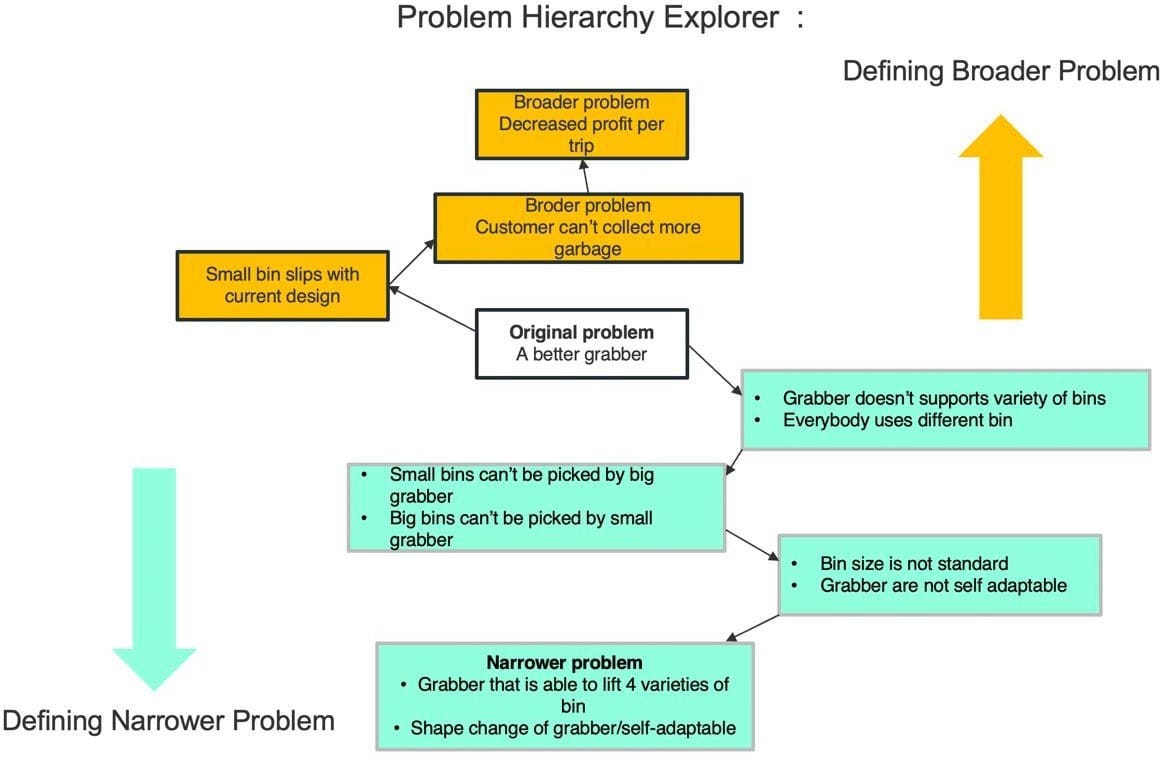

Improving productivity & convenience of Garbage Collecting Companies, who are customers of the Client. These companies were facing challenges in garbage collection – increased manual handling, reduced productivity and increased garbage collection costs. The main problem was the design of a grabber caliper which could not hold all sizes of the dustbins leading to increased manual handling of smaller size bins.

Two design concepts which have been implemented leading to significant customer benefit – improved productivity and lower garbage collection costs.

The client is the India Design & Engineering Services Centre of a diversified global manufacturer and solutions provider with annual revenue of over $8 billion. The organization delivers innovative equipment and components, consumable supplies, aftermarket parts, software and digital solutions, and support services through five operating segments. A group company is a premier manufacturer of ultra-durable, high-productivity, custom-configured garbage trucks, and Connected Collections® technology that help customers achieve the lowest Total Cost of Collection (TCC). The garbage trucks manufactured by this organization has a pickup assembly which has two calipers which are operated with hydraulic mechanism for gripping the dustbins and emptying them into a large collector bin mounted on the garbage collection truck. The gripping and unloading of the dustbins in the bigger bin is controlled by the vehicle operator without getting out of the cabin. These garbage trucks are sold to “Garbage Collection Companies”.

During garbage collection, the vehicle driver had to get down from the vehicle to pick up smaller bins which could not be gripped by the gripper and had to manually empty them in bigger container mounted on the vehicle. This reduced the productivity of garbage pick up and increased cost of operations by way of putting up an extra man and / or offering overtime which was a significant cost.

Technical Problem: The garbage caliper could not move beyond a certain point to grip smaller dustbins. This was because current design constraints.

Key Business Constraints: The design modification cost must be nil or minimum possible. The time to introduce improved design must be minimum.

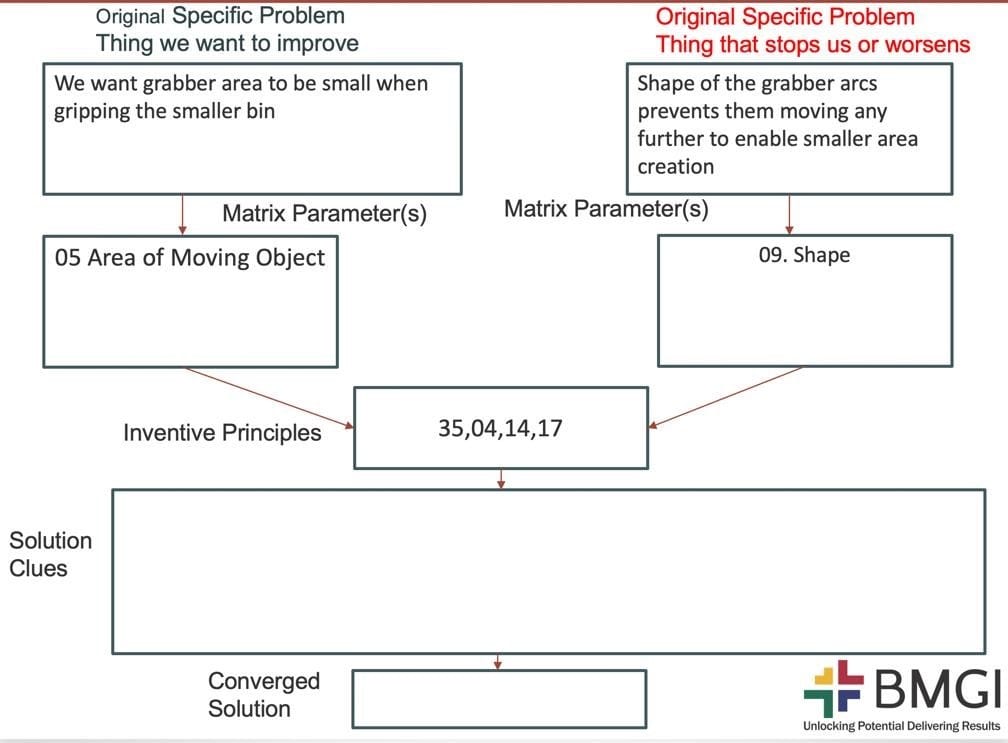

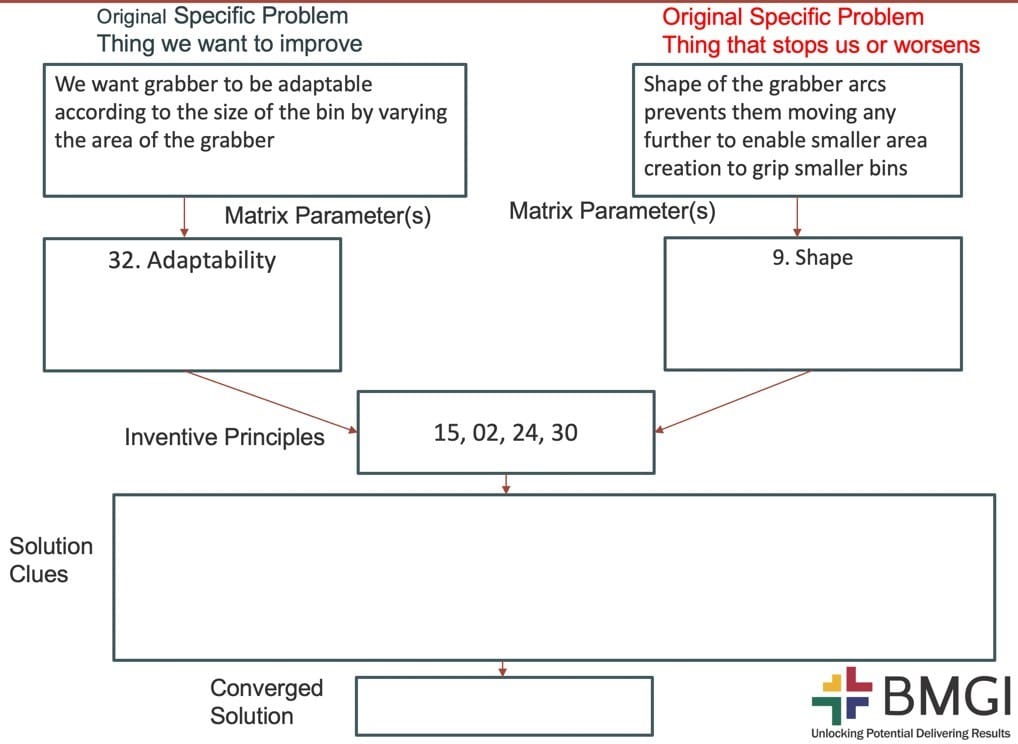

BMGI worked with the project team to solve this problem. This was done through workouts with the team. The workout first imparted knowledge on the TRIZ methodology and associated techniques followed by the application of the TRIZ methodology on the specific problem.

The key steps were as follows:

Inventive Principles To Be Used To Solve Such Contradiction : Segmentation (1), Taking Out (2), Local Quality (3), Another Dimension (17), The Other Way Round (13), Curvature (14), Nested Doll (7), Flexible Shells / Thin Films (30), Asymmetry (4), Intermediary (24), Copying

Inventive Principles To Be Used To Solve Such Contradiction : Dynamics (15), Preliminary / Prior Action (10), Periodic Action (19), Beforehand Cushioning (11), Partial or Excessive Action (16), Skipping (21), Copying (26), Mechanical Vibration (18), Thermal Expansion (37), Discarding & Recovering (34), Preliminary Anti-Action (09), Continuity of Useful Action (20)

Breakthrough Management Group International (BMGI), a global consulting firm with a strong focus on delivering results and has delivered cumulative benefits to its clients worth several billion dollars with an engagement ROI of 5:1 to 20:1. BMGI specialises in enabling organisations drive profitable growth and innovate. Solutions include building innovation opportunities portfolio for driving growth, breaking optimization barriers to multiply profits and transform customer experience. We have developed several methodology & framework-based assets to enable client success. BMGI’s clients include leading Fortune 1000 Global companies and other Indian companies from diverse industries such as financial services, IT/ITES, airlines, chemicals, FMCG, discrete manufacturing, telecommunications, petrochemical, textiles, healthcare & energy.