The Agony and the Ecstasy of Innovation

Introduction: A Journey of Ambition and Challenges

Drawing inspiration from “The Agony and the Ecstasy,” the story of Michelangelo’s unwavering dedication to his craft, Ola Electric’s journey in the electric vehicle space reflects a similar blend of bold ambition, rapid growth, and inevitable challenges. Like Michelangelo, who faced immense setbacks while creating masterpieces like the Sistine Chapel that stood the test of time, Ola Electric is navigating its own trials in revolutionizing the EV industry in India. Despite encountering hurdles in product quality and customer service, their commitment to innovation and excellence is reminiscent of the artist’s perseverance. Tesla, too, faced similar challenges while scaling its operations and meeting the increasing demand for its electric cars. The lessons learned by companies like Tesla can offer valuable guidance for Ola Electric.

Growing Pains: The Agony of Scaling

Ola Electric recorded its lowest sales in 2024 at 23,965 vehicles in September, a decline of 11% month-on-month, while the other key players – Bajaj Auto, TVS and Ather Energy saw an increase in monthly sales in September. The company has also experienced a decline in its market share in the electric two-wheeler segment, dropping from a peak of 49% in the first quarter of FY25 to 27% in September 2024. Additionally, its share price has decreased by approximately 35% from its peak value.

The declining sales come at the back of a surge in customer complaints. Ola is receiving an average of 80,000 complaints per month, with some days seeing up to 6,000-7,000 complaints.

Ola has already taken significant steps in addressing customer service challenges. The recently unveiled Ola Hyper Service initiative showcases a strong commitment to enhancing customer experience. This strategy includes expanding to 1,000 service centers by December, training 1 lakh third-party mechanics to be EV-ready by 2025, and introducing features like a Quick Service Guarantee with one-day resolutions, AI-powered proactive maintenance alerts, and enhanced customer support. These developments highlight Ola’s dedication to improving service reliability and meeting customer needs, though these actions are only likely to address the complaints related to customer service delays, but not reduce the number of unhappy customers complaining about the vehicle each month.

While we do not have the specifics, based on certain assumptions and calculations, we expect the above actions to take approximately USD 100-125 Million. That is a huge spend commitment to work on reactive solutions.

Additionally, if the complaints continue at the current rate, the cost of unhappy customers for Ola Electric could potentially exceed USD 150 million annually when considering lost revenue, increased customer acquisition costs, reputation damage, complaint handling, litigation / legal expenses, and missed growth opportunities.

Shifting from Reactive to Proactive Approach

While these efforts are a much-needed response to existing issues, they primarily focus on reactive measures. Ola’s true potential lies not just in reacting to problems but in proactively preventing them from arising in the first place. This approach requires a shift towards designing a robust product that minimizes the need for service interventions, setting a new standard for innovation and excellence in the EV sector.

Learning from Industry Leaders: Lessons from Tesla and NIO

Tesla’s Path to Quality Improvement

In its early years, Tesla struggled with product quality issues and delays in service response, which threatened its reputation. To tackle these challenges, Tesla adopted Design for Six Sigma (DFSS) to focus on designing products that minimize defects right from the start. They also implemented Lean methodologies to optimize service operations, speeding up the resolution of customer issues and enhancing the overall customer experience.

NIO’s Strategy for Rapid Service and Consistency

NIO, a major player in the Chinese EV market, faced similar challenges related to service efficiency and quality. NIO leveraged Lean Six Sigma techniques to reduce process inefficiencies, streamline service operations, and build a customer-centric approach. This methodology enabled them to handle service requests with greater accuracy and faster response times, directly boosting customer trust and loyalty.

The Ecstasy of Excellence

1. Achieving Zero-Defect Reliability with Design for Six Sigma (DFSS)

To move beyond reactive solutions, Ola should adopt Design for Six Sigma (DFSS) to aim for zero-defect reliability in their scooter designs. This approach focuses on preventing issues from occurring in the first place by embedding quality into the product design itself. The DFSS strategy would not only reduce the need for frequent maintenance but also elevate the overall customer experience.

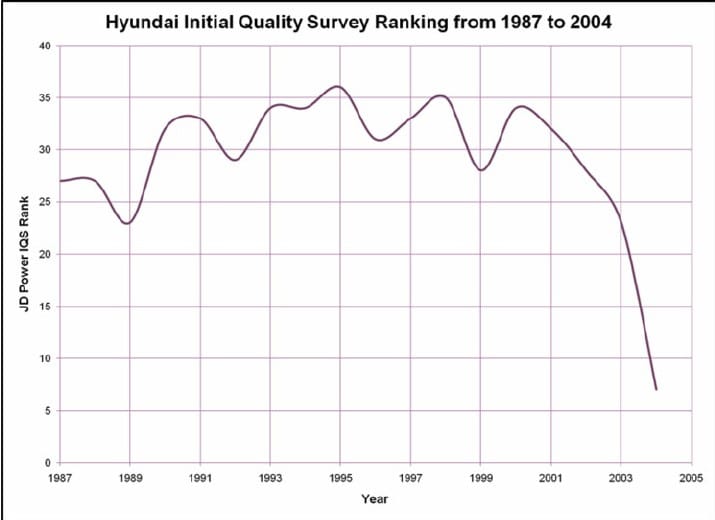

Let us take the case of Hyundai Motors. After consistently ranking in the 25-3 5 range over nearly a decade, it finally broke into the Top 10 list based on the JD Power Initial Quality Study (IQS) Ranking, as shown in the graph. Hyundai adopted Design for Six Sigma (DFSS) in 2002. This was supposedly verified by GM that had a variety of internal quality metrics, and collected benchmarking data from Hyundai. It was apparent that Hyundai’s quality assent was rapid, significant, and recognized by the customer. GM then adopted the structured DFSS activity employed at Hyundai Motors in Korea, which was claimed to be a key driver of the very dramatic rise in their quality.

5 range over nearly a decade, it finally broke into the Top 10 list based on the JD Power Initial Quality Study (IQS) Ranking, as shown in the graph. Hyundai adopted Design for Six Sigma (DFSS) in 2002. This was supposedly verified by GM that had a variety of internal quality metrics, and collected benchmarking data from Hyundai. It was apparent that Hyundai’s quality assent was rapid, significant, and recognized by the customer. GM then adopted the structured DFSS activity employed at Hyundai Motors in Korea, which was claimed to be a key driver of the very dramatic rise in their quality.

2. Leveraging Six Sigma to Minimize Defects and Drive Quality Improvements

As Ola seeks to enhance product quality, adopting Six Sigma methodologies can be a game-changer in systematically reducing manufacturing defects. Six Sigma uses data-driven approaches to identify and eliminate the root causes of issues, aiming for near-zero defects in all aspects of the business. By integrating Six Sigma into both manufacturing and service processes, Ola can improve consistency, reduce variability, and deliver higher standards of excellence.

3. Achieving the Ideal Final Result (IFR): A Maintenance-Free Scooter

A visionary goal for Ola would be the pursuit of the Ideal Final Result (IFR)—designing a scooter that requires no maintenance or repairs at all. This approach challenges Ola to innovate beyond conventional designs, striving for breakthroughs in material durability, modular components, and AI-driven predictive maintenance.

The vision is to create a product that remains reliable and maintenance-free, similar to consumer electronics like Smart Phones and TVs.

4. Long-Term Vision: Reducing Dependency on Mechanics

While training 1 lakh third-party mechanics is a step towards immediate improvements, the long-term vision should focus on reducing this dependency. Ola should aim to design scooters that are self-sustaining, self-diagnosing, and can be easily maintained by the users themselves. The goal should be a three-year plan towards a service-free ecosystem, where AI-driven diagnostics and product durability ensure that issues are resolved even before they occur. The vision is to create a product that is self-maintained at best, similar to consumer electronics like Laptops.

5. Enhancing Customer Experience through Process Standardization

Ensuring a consistent and high-quality customer experience across various touchpoints is crucial for building brand loyalty. Process Standardization plays a vital role by defining clear, repeatable procedures that all service personnel must follow. Standardized processes guarantee that every interaction with the customer—whether during the initial purchase, routine servicing, or addressing complaints—meets Ola’s high standards. This approach helps in delivering a seamless and reliable experience, instilling confidence in the brand and enhancing overall customer satisfaction.

Conclusion: Redefining the Future of Electric Mobility

Just as Michelangelo’s journey in “The Agony and the Ecstasy” reminds us that greatness is born out of struggle and ambition, Ola Electric’s evolution is defined by its vision to turn challenges into triumphs. While their recent efforts to enhance service operations are commendable, the true path to excellence lies in shifting from reactive to preventive strategies. By embracing Design for Six Sigma (DFSS), aiming for the Ideal Final Result (IFR) of a maintenance-free scooter, and establishing a service-free ecosystem, Ola Electric can set a new standard in the EV industry as well as improve its financial performance by adding approximately USD 40-50 Million to its profits over the next 12-18 months. This approach is not just about improving the present; it’s about redefining the future of electric mobility.

At BMGI, we have a deep understanding of these methodologies, having successfully guided numerous clients, including those in the automotive industry, through transformative business and operational strategies.

About BMGI

Breakthrough Management Group International (BMGI), a global consulting firm, partners with organizations to transform their business performance with a strong focus on delivering results. Over the last 30+ years, BMGI has delivered an engagement ROI of 5:1 To 20:1. We deliver:

- 1.5-2X of market growth rate for large enterprises

- Multi-fold growth in 3-5 years for small to mid-sized businesses, and

- 1-5% of Revenues added to the bottom line within 9-12 months for companies of various sizes.

Our Mantra: You win, we win. Simple.

We are agnostic to the industry, function and size of the organization. We work with clients across industries, across the breadth of the organization, ranging from startups to multi-billion dollar MNCs. Some of our prestigious clients include Axis Bank, ICICI Bank, Flipkart, ITC, Infosys, TCS BPO, Marico, Reliance Industries, Sudarshan Chemicals, HUL, Jyothy Laboratories, Garware Polyster, Gala, Dr Reddy’s, Lupin, Apollo Tyres, SKF, VW, Daimler, John Deere, TVS Motors.